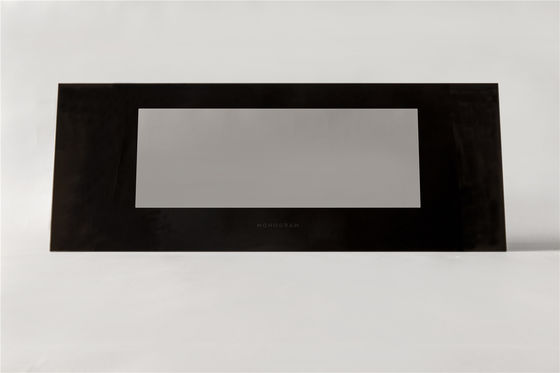

OEM Flat Polish Edge Gray Color Oven Tempered Glass With Logo Printing

Oven tempered glass description:

The glass used in oven doors must withstand high heat while simultaneously keeping the temperature inside the oven at a steady temperature and providing a clear view inside. Not all glass is right for the job. Tempered glass has the desirable characteristics thanks to its durability, safety and low conduction.

Tempered glass is the less expensive alternative, and is best for lower temperature applications. It can withstand constant temperatures of up to 470 degrees F. Tempered glass is regular glass that has been strengthened through thermal or chemical treatment. Tempering not only strengthens the glass, but also changes its breakage pattern, causing it to shatter into small pieces instead of large sharp angles, reducing the chance of injury.

Parameters of oven tempered glass:

Border color: Black,red,white etc.

Safety of heat-resistance: ≤760℃

Colors: clear, black, white, ultra clear

Structure: solid

Density(rho): about 2.6 g/cm3

Material: Normal clear float glass

Edge: Edges ground, straight edge, flat edge, round edge, bevel edge

Corner:safety Corner and R corner

| Coefficient of Linear Thermal Expansion α(20 - 700°C) |

(0 ± 0.5) x 10-6 /K |

| Thermal Capacity (CP20 - 100°C) |

0.8x103J/(kg x k) |

| Thermal Conductivity λ(90°C) |

1.6W/(m x k) |

| Resistance to Thermal Gradients(RTD) |

Tes, max1) ≤ 700°C |

| Resistance to Thermal Shock |

Tes, max ≤ 700°C |

| Working temperature |

760°C |

Lead time for Oven tempered glass

| Order QTY |

sample |

500 |

2000 |

5000 |

10000 |

| Lead time |

5 days |

10 days |

15 days |

20 days |

25 days |

Oven tempered glass producing:

Tempered glass is a type of glass with even compressive stress on the surface which is made by heating float glass to nearly softening point and then cooling it down rapidly by air. During the instant cooling process, the exterior of glass is solidified due to rapid cooling while the interior of the glass is cooled down relatively slowly. The process will bring the glass surface compressive stress and the interior tensile stress which can improve the mechanical strength of glass by germination and result in good thermal stability.

Description of screen printing on oven tempered glass:

Printing color for oven tempered glass is inorganic glaze (also known as ink), printing to the glass surface, and then by drying, tempered or hot processing, the glaze permanent dry or sintering in the glass surface and get a kind of wear-resisting, resistance to acid and alkali of decorative glass products. This product has a high functional and decorative. It has many different colors and patterns, such as strip, mesh and the electric design and so on. Also can according to customers' different needs further design pattern.

Please Note:

The specification should be confirmed before put the sheet glass into the toughening furnace, the tempered glass can't be cut anymore after out of the toughening furnace, otherwise it will be broken.

Oven tempered glass edges

We create oven tempered glass at whatever length, depth, and thickness you need. Most of the times these oven tempered glass have exposed edges, giving you the option of adding another level of detail to better reflect your personal style. Our seamed edge comes standard with your order. If the edge is going to show, consider a rounded (pencil) or flat edge, as preferred by many as it gives a more finished look when edges are visible.

After choosing whether or not you want a rounded or flat edge, you get to choose between a polish or grind. A polish gives a shiny and glossy finish, while a grind provides a frosted matte finish. This small detail can impact the overall effect you want to create in your space.

To get a quick and satisfied feedback to your inquiry about oven tempered glass. Please advise:

1. Tempered glass material. Thickness? Size?

2. Usage. Please say out loud. For touch panel? Cover glass? Hosehold appliance glass ? Switch, socket glass?

3. Drawing / Design draft of the glass. (Our experienced technical engineers will follow up and suggest options to help you develop.)

4. Requirements in details.

5. Quantity.

6. Others you think necessary.

FAQ

Q:Can you do the oven tempered glass as customized?

A:Yes, we could produce the glass according to your requirements. OEM and ODM is welcome.

Q. How do I get oven tempered glass price?

A. Kindly advise us the glass usage, glass thickness, size, quantity, whether need to further process and other detailed requirements etc, We will work on it and reply ASAP. The more details you provide the more accurate and quicker you get the quotation.

Q. How can I get oven tempered glass samples to check your quality?

A. After all details and requirements are confirmed, we can offer free samples by DHL, UPS and FedEx, and you only need to pay the freight.

Q. How do you control oven tempered glass quality?

A. High quality raw material float glass, such as Yaohua Pilkington Glass, etc.

B. Automatic tempering furnace, automatic cutters, double edge grinding machine to reduce defective rate.

C. Professional inspection team and devices during and after production to make sure 100% compliance with the request of clients.

D. Professional packing team to ensure glass safe.

E. After sales service to guarantee the quality.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!