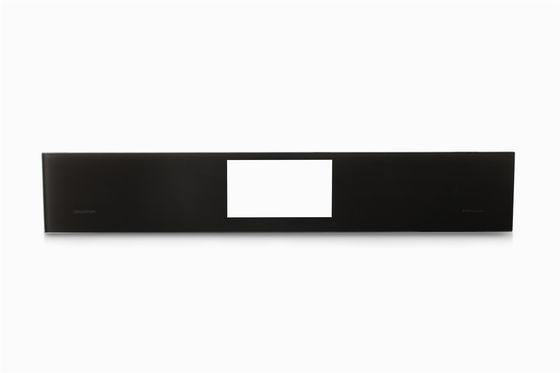

Oven Door Tempered Glass Control Panel With Gray Color Logo Printed

Description of glass control panel:

The glass used in oven doors must withstand high heat while simultaneously keeping the temperature inside the oven at a steady temperature and providing a clear view inside. Not all glass is right for the job. Tempered glass has the desirable characteristics thanks to its durability, safety and low conduction.

| Holes, edges, shape |

customized |

| OEM/ODM |

available |

| Function |

decorate, touch screen, front frame, covers, |

| Appearance and Feature |

extra clear, high hardness-6H,7H,9H, anti-scratched, anti-reflective, anti-shock, anti-AR, color coated |

| Thickness |

3.0mm, 4.0mm, 5.0mm,6.0mm etc. |

| Finished product name |

Silk printed glass panel, cover pane, acrylic sheet, decorate covers, touch switch glass panel, |

Features of tempered glass control panel:

1. It needs good mechanical strength and good bending strength;

2. It is required to have high heat-resistant temperature and can withstand long-term baking of high-temperature oven without cracking;

3. The softening temperature should be higher, the softening temperature should be high, and the glass can be used at a relatively high temperature;

4. Chemical stability is good, the general oven will often contact with a variety of food or other chemical substances, glass can not be required to react with it. At the same time, it is required that toxic and harmful substances will not be released under high temperature.

Glass control panel producing:

Tempered glass is obtained by cutting the general annealed glass into the required scale, then heating it to 700 degrees of cloth near the softening point, and then cooling quickly and evenly. According to the different thickness of glass, the heating and cooling time is not the same). After tempering, the glass surface forms uniform compressive stress, while the internal part is tensile stress, which makes the bending and impact strength of glass improve, and its strength is about four times higher than that of the general annealed glass. Tempered glass can no longer be cut, ground or damaged, otherwise it will be "broken" due to the damage of uniform pressure stress balance. This is how the toughened glass panel is made.

OEM Service for glass control panel:

We temper glass right here in our horizontal continuous tempering furnace. That means we can craft the glass to your exact specifications. Drill holes, grind edges, and make all necessary customizations to make it the perfect fit for your project, whether it’s tempered glass meant to replace fireplace door or custom tempered glass shelves. Then we heat treat it in our unique tempering furnace and ship it to you.

If you’re not sure whether or not your project or item should involve tempered or another kind of glass, feel free to contact us and we’ll walk you through some of the ins and outs regarding applicability, pricing, availability, etc.

Glass control panel testing items:

Hardness of chisel, Adhesion, Wear test, Color fastness/UV resistance, Stain resistance (food stain), Stain resistance (electrical cleaner), Grease resistance, Steam resistance, Grease resistance, Color stability at high temperature, Grease resistance, etc.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!